Design of acoustic emission detection system for fastener and characteristic analysis of damage signal

-

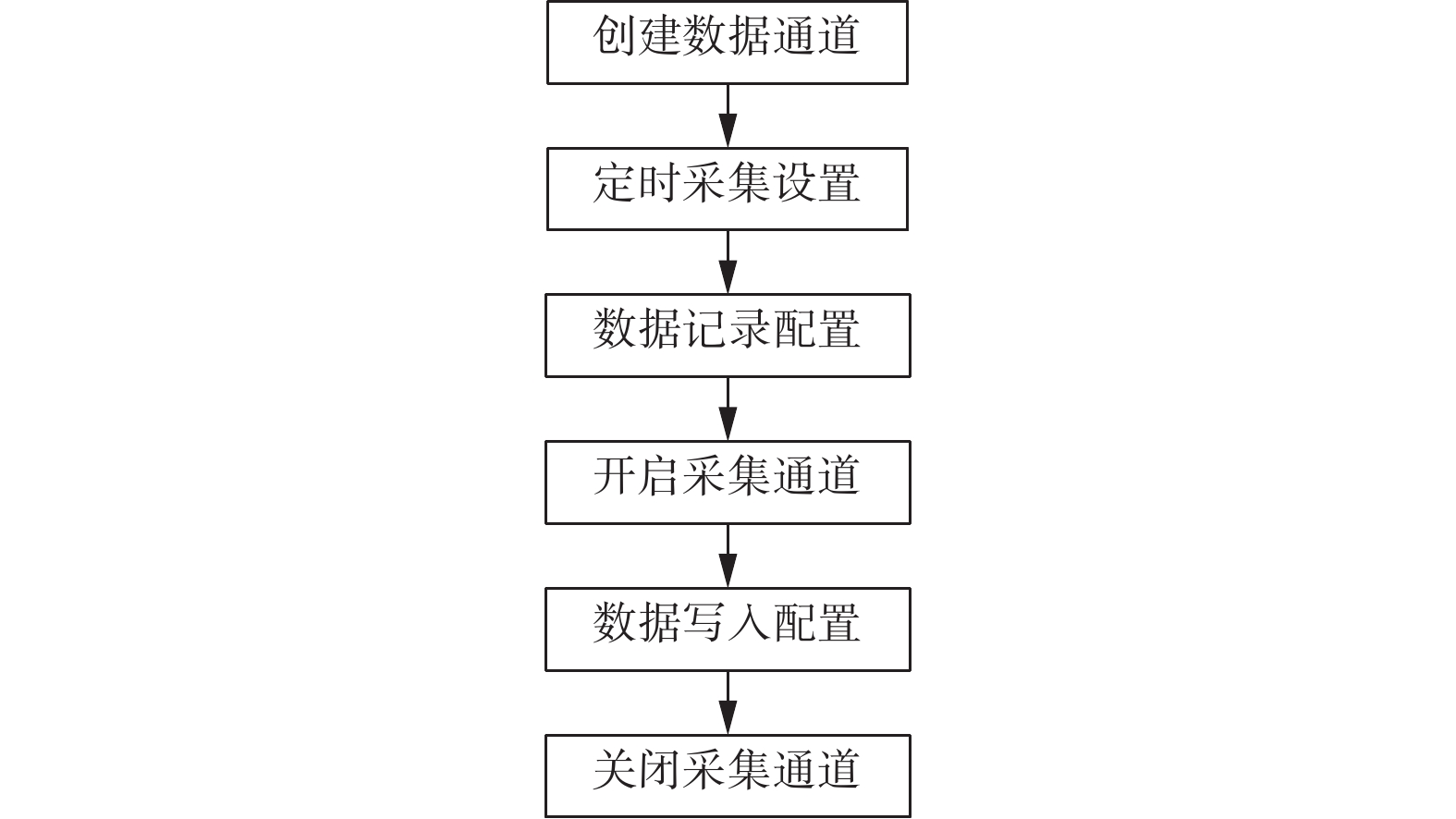

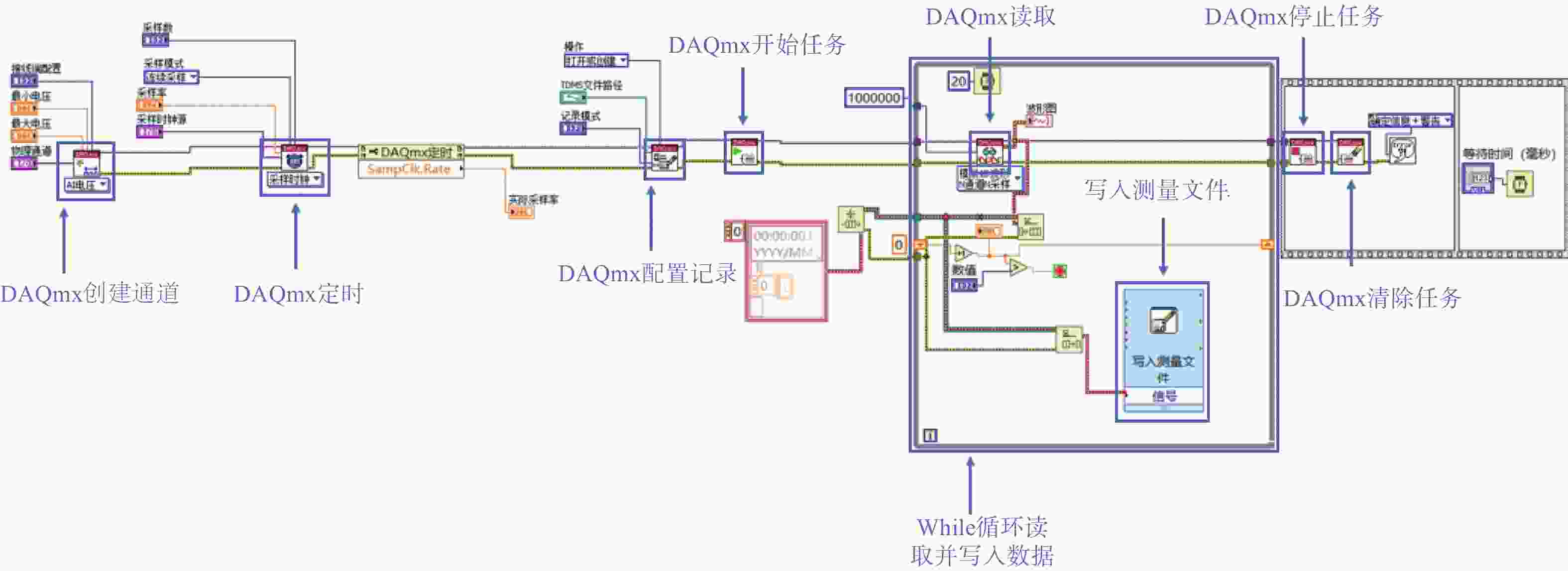

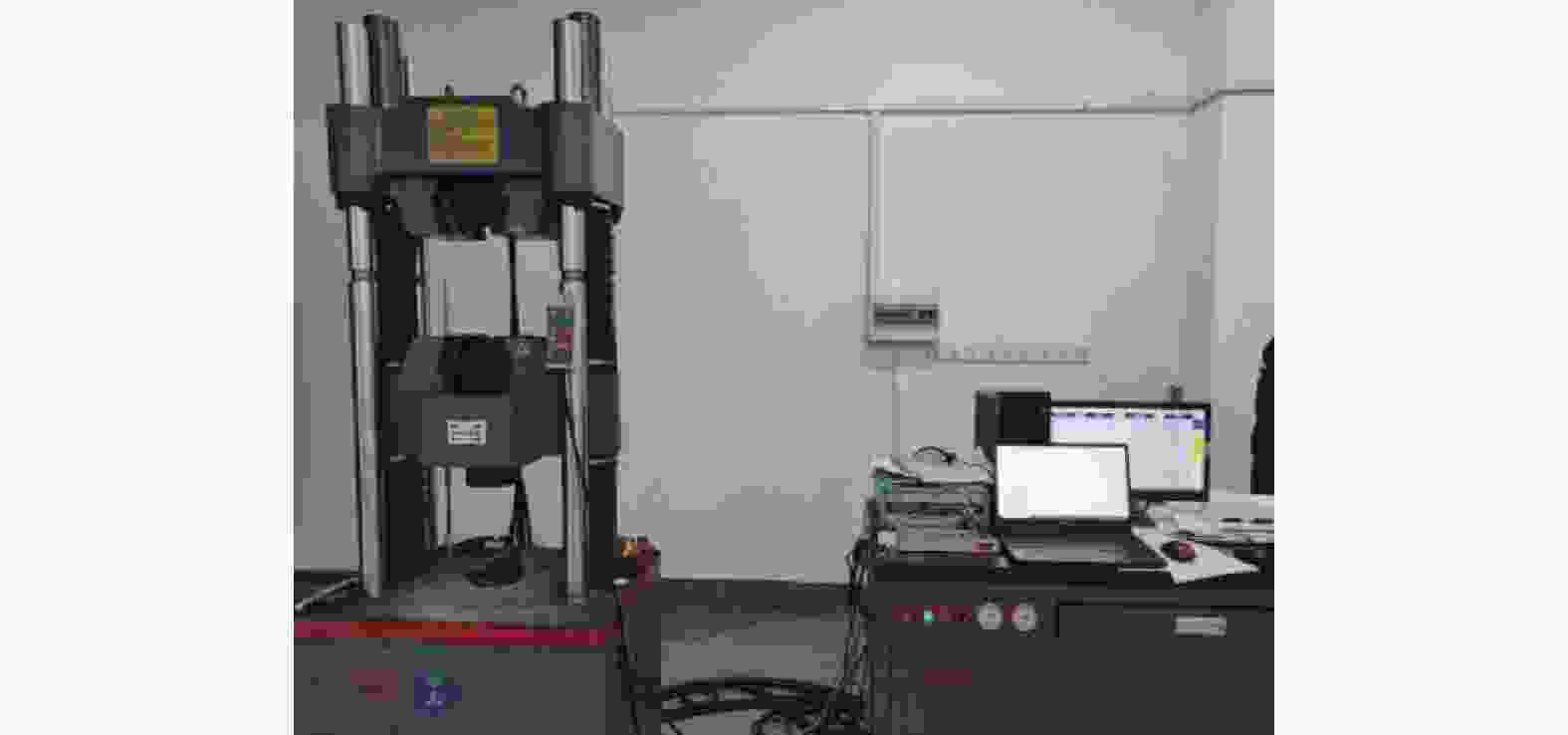

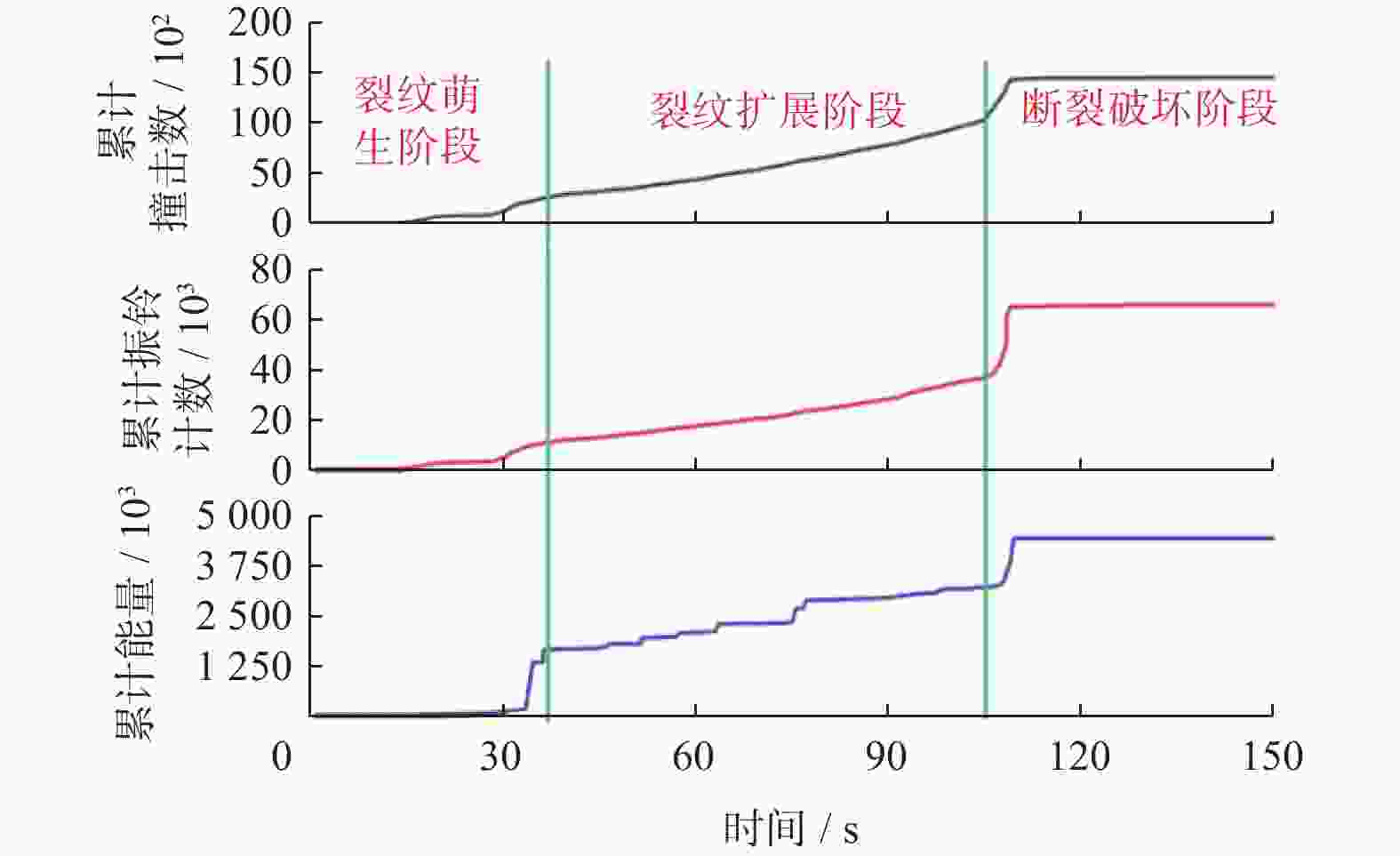

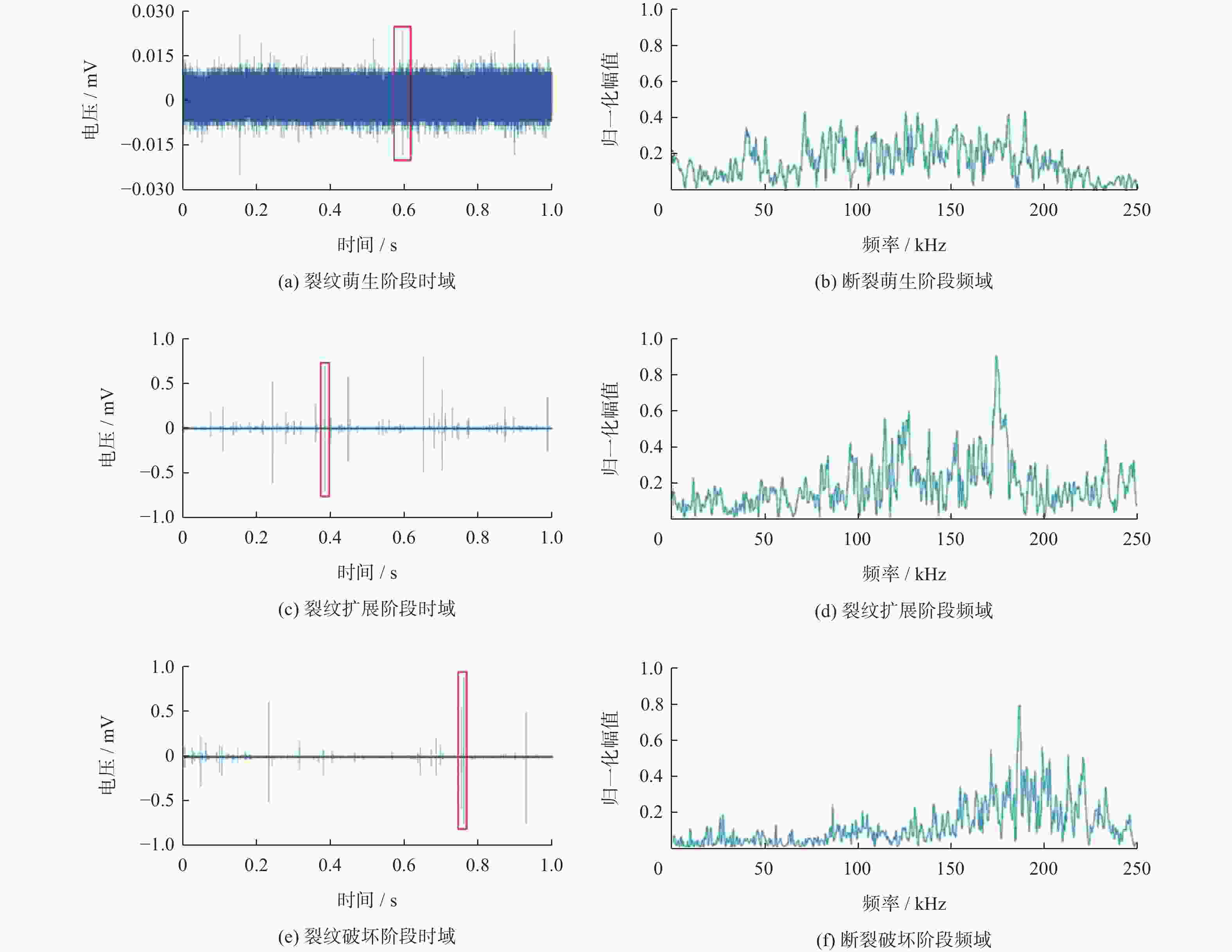

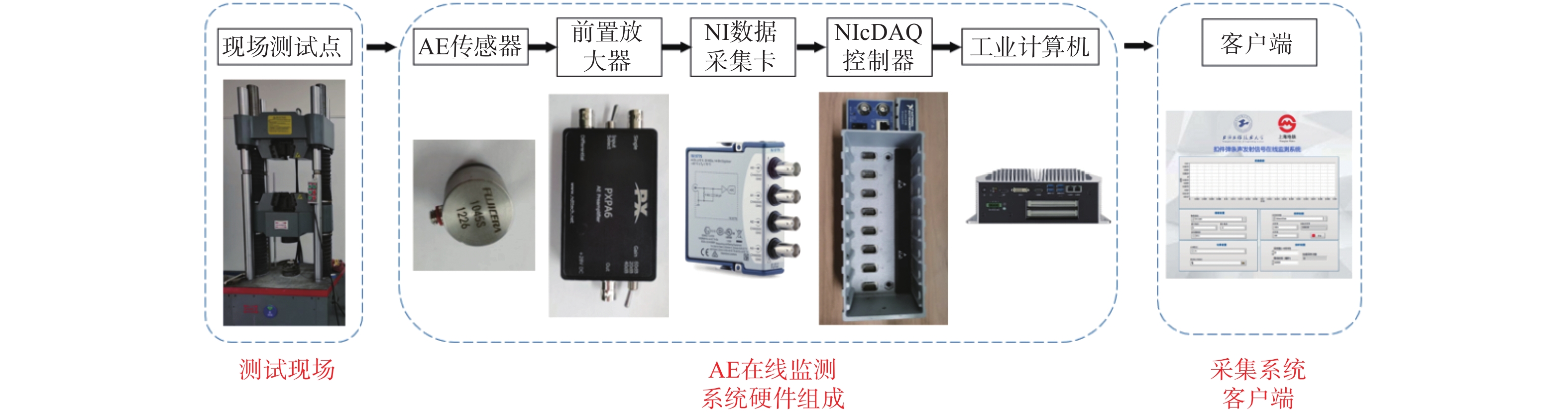

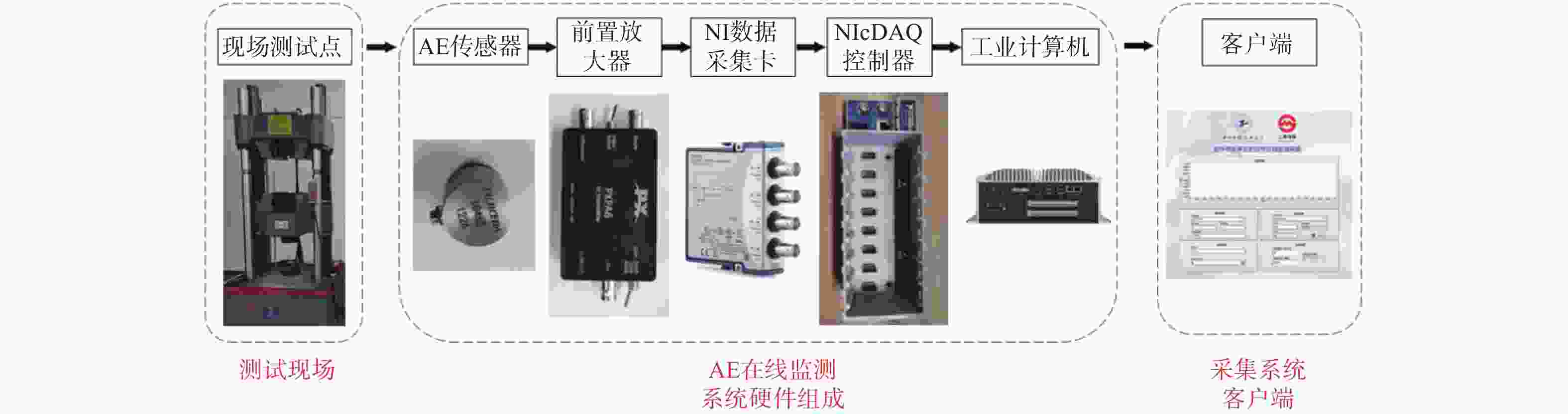

摘要: 扣件弹条断裂病害是列车运行安全的危险源之一。扣件弹条状态检测以人工巡检方式为主,难以及时检出,且缺乏行之有效的无损检测方法。将声发射技术运用到扣件弹条的损伤检测中,开发了扣件声发射信号采集系统;搭建了B型弹条静载压缩试验系统,采集得到B型弹条折断破坏过程中完整的声发射信号。利用声发射参数分析法得到弹条折断过程中的3个损伤阶段,裂纹扩展阶段声发射事件较为活跃,幅值较高。基于声发射波形分析法得到不同损伤阶段的声发射信号特征,从裂纹萌生、扩展到断裂破坏阶段声发射信号的能量占高的频带依次增大,且越到损伤后期声发射信号高频成分占比越多。Abstract: Fracture disease of fasteners and elastic strips is one of the risk sources of train operation safety. The fastener sling status detection is mainly based on manual inspection, which is difficult to detect in a timely manner, and there is a lack of effective non-destructive testing methods. The acoustic emission technology was applied to the damage detection of fastener sling, and a fastener acoustic emission signal acquisition system was developed; type B sling static load compression experiment system was built; the complete acoustic emission signal during the fracture and damage of the type B strip was acquired. Using the acoustic emission parameter analysis method to analyze the three damage stages of the slug fracture process, the crack extension stage acoustic emission events are more active and the amplitude is higher. The characteristics of the acoustic emission signal at the different damage stages were obtained by acoustic emission waveform analysis method, and the energy of the acoustic emission signal from the crack initiation to the extension to the fracture damage stage increased in the frequency band, and the later stage of damage, the higher frequency component of the acoustic emission signal.

-

表 1 监测系统主要硬件型号

Table 1. Main hardware models of the monitoring system

序号 名称 型号 单位 数量 1 声发射传感器 Fuji 1045S 个 1 2 前置放大器 PXPA6 个 1 3 数据采集卡 NI 9775 个 1 4 数据采集控制器 NI cDAQ-9188 个 1 5 工业计算机 ARK-3500 个 1 -

[1] 林菲, 杨子明, 李永光, 等. 钢轨扣件检测技术研究[J] . 中国铁路,2019(6):103 − 110. [2] 王开云. 轨道交通结构服役性能演变与安全控制[J] . 科学报,2019,64(25):2564 − 2565. [3] 侯博文, 李佳静, 高亮, 等. 基于脉冲激励下钢轨振动响应的扣件失效识别方法[J] . 工程力学,2021,38(2):122 − 133. doi: 10.6052/j.issn.1000-4750.2020.04.0210 [4] 孙旭, 王平. 高速铁路扣件失效对车辆−轨道耦合系统动态响应的影响[J] . 铁道学报,2022,44(8):108 − 116. doi: 10.3969/j.issn.1001-8360.2022.08.012 [5] 廖进, 吴松荣, 刘东, 等. 车载式地铁轨道缺陷巡检系统设计[J] . 现代城市轨道交通,2020(4):11 − 16. [6] 宋浩然, 田新宇, 戴鹏, 等. 高速铁路综合巡检车研制[J] . 中国铁路,2021(6):28 − 34. [7] 张耀新. 铁路扣件的图像预处理和缺失检测的方法研究[D]. 西安: 西安电子科技大学, 2021. [8] 李欢, 柴晓冬, 彭乐乐, 等. 轨道扣件检测系统设计与分析[J] . 计算机测量与控制,2019,27(2):43 − 46, 64. [9] SIKDAR S, OSTACHOWICZ W, PAL J. Damage-induced acoustic emission source identification in an advanced sandwich composite structure[J] . Composite Structures,2018,202:860 − 866. -

下载:

下载: