Visual measurement method for aircraft milling parts' guide hole with interference area

-

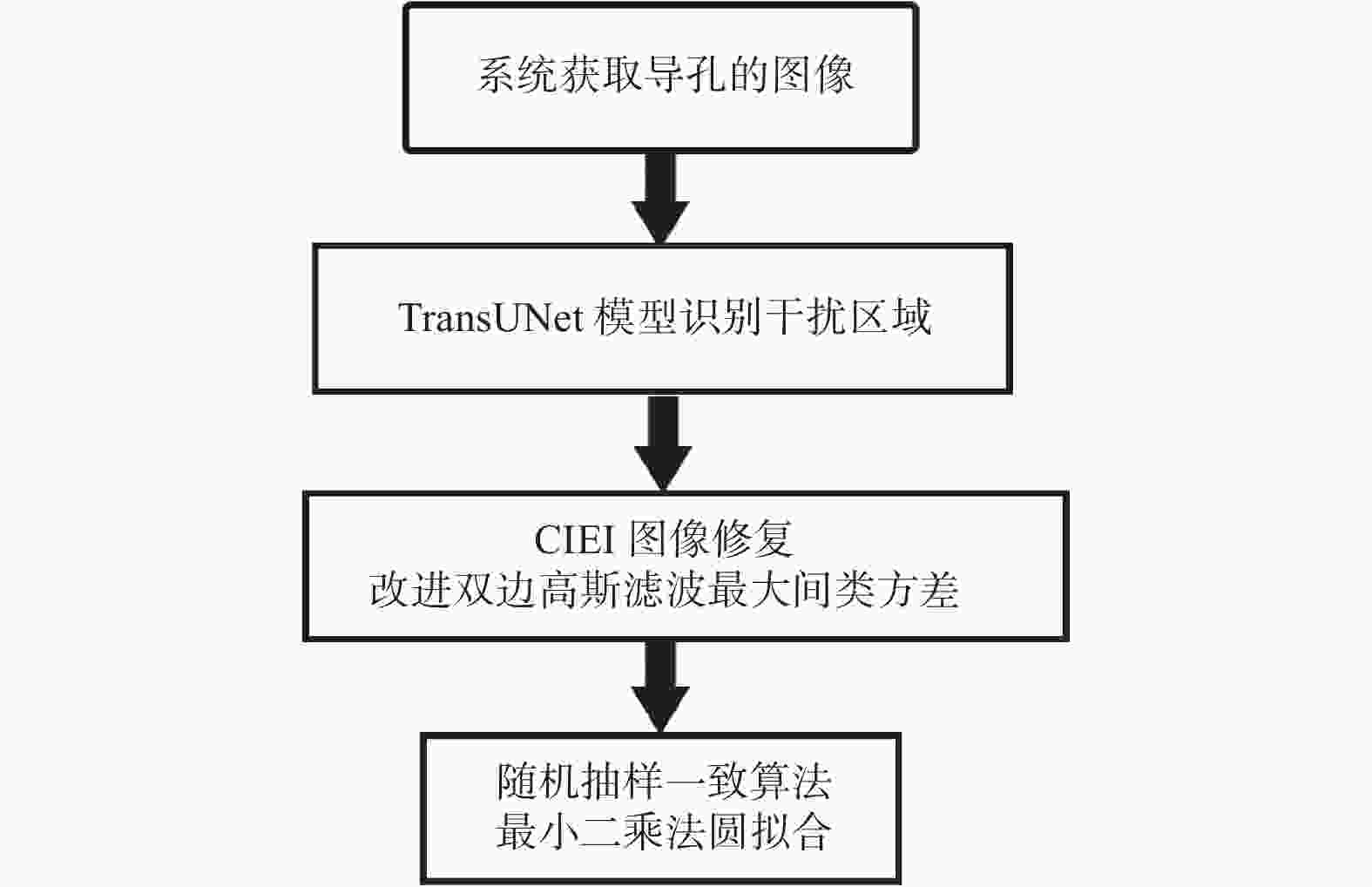

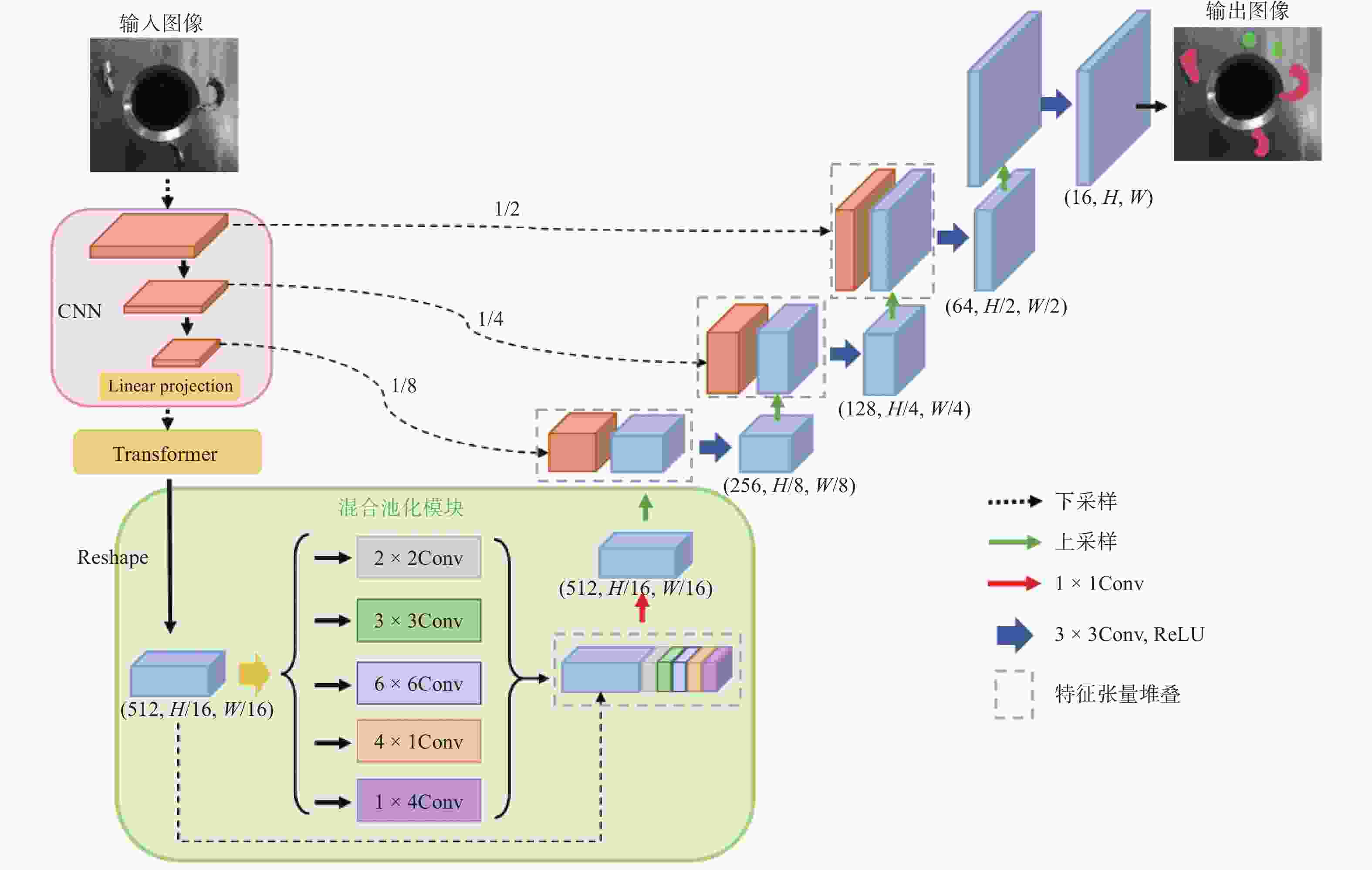

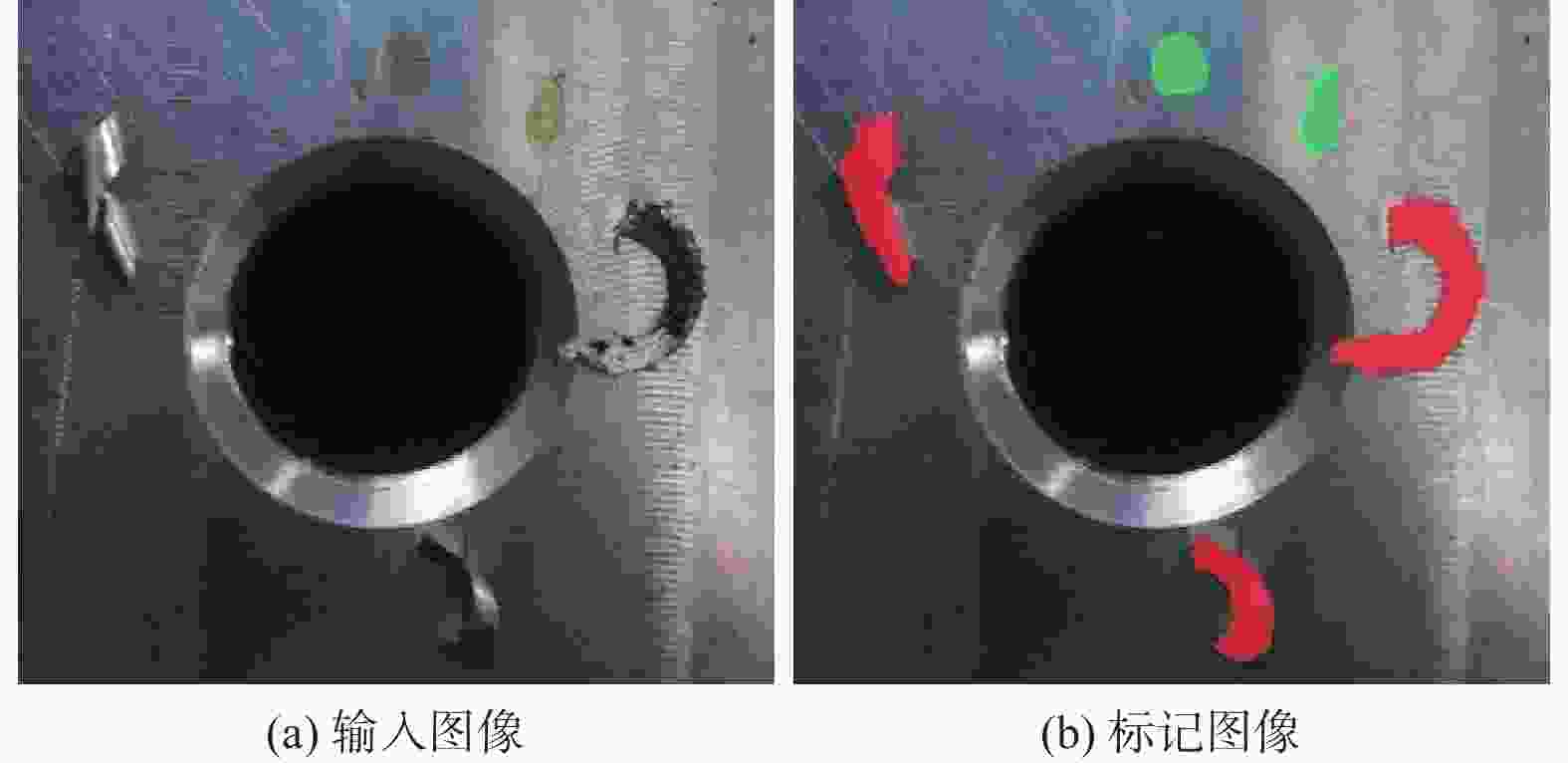

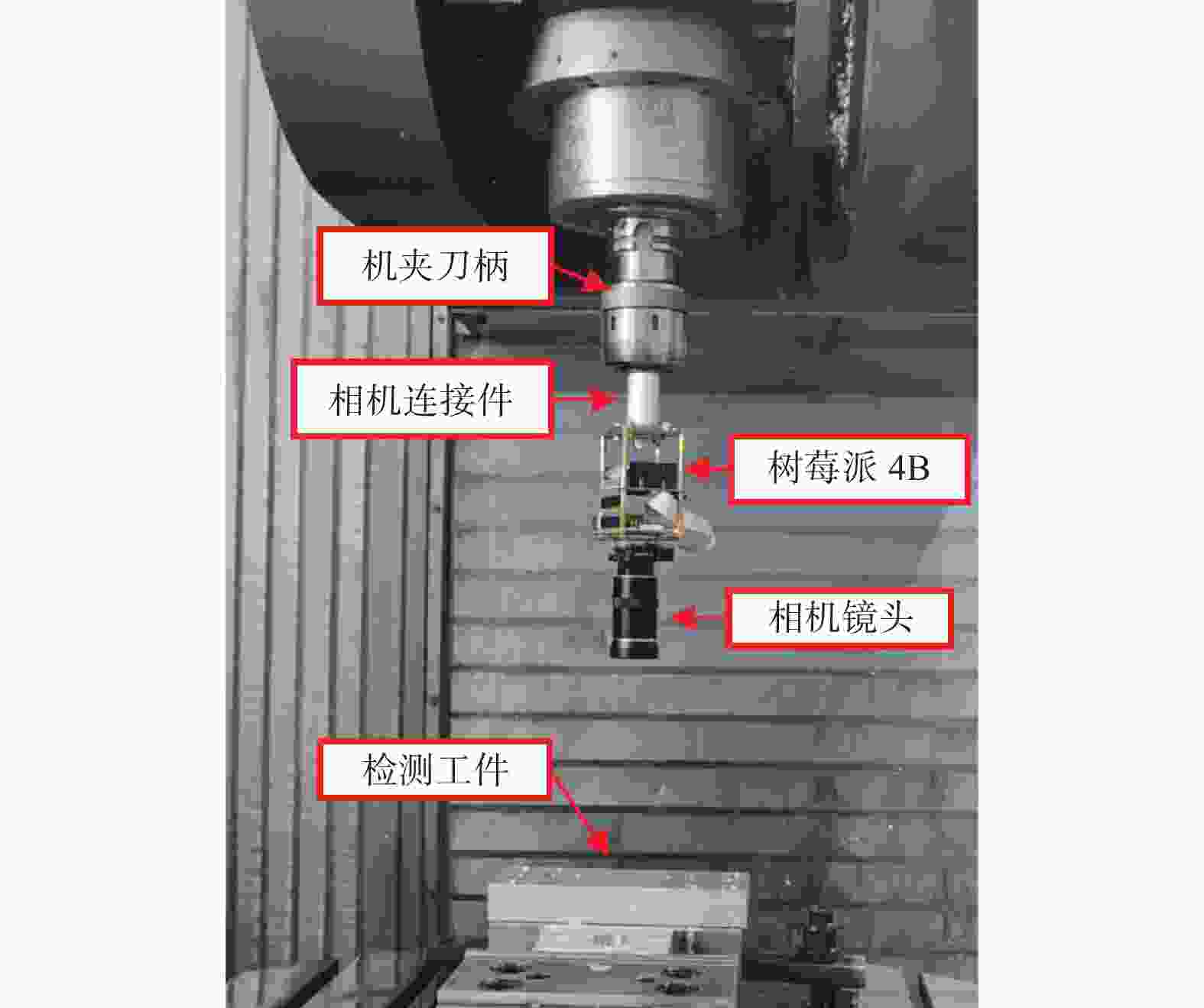

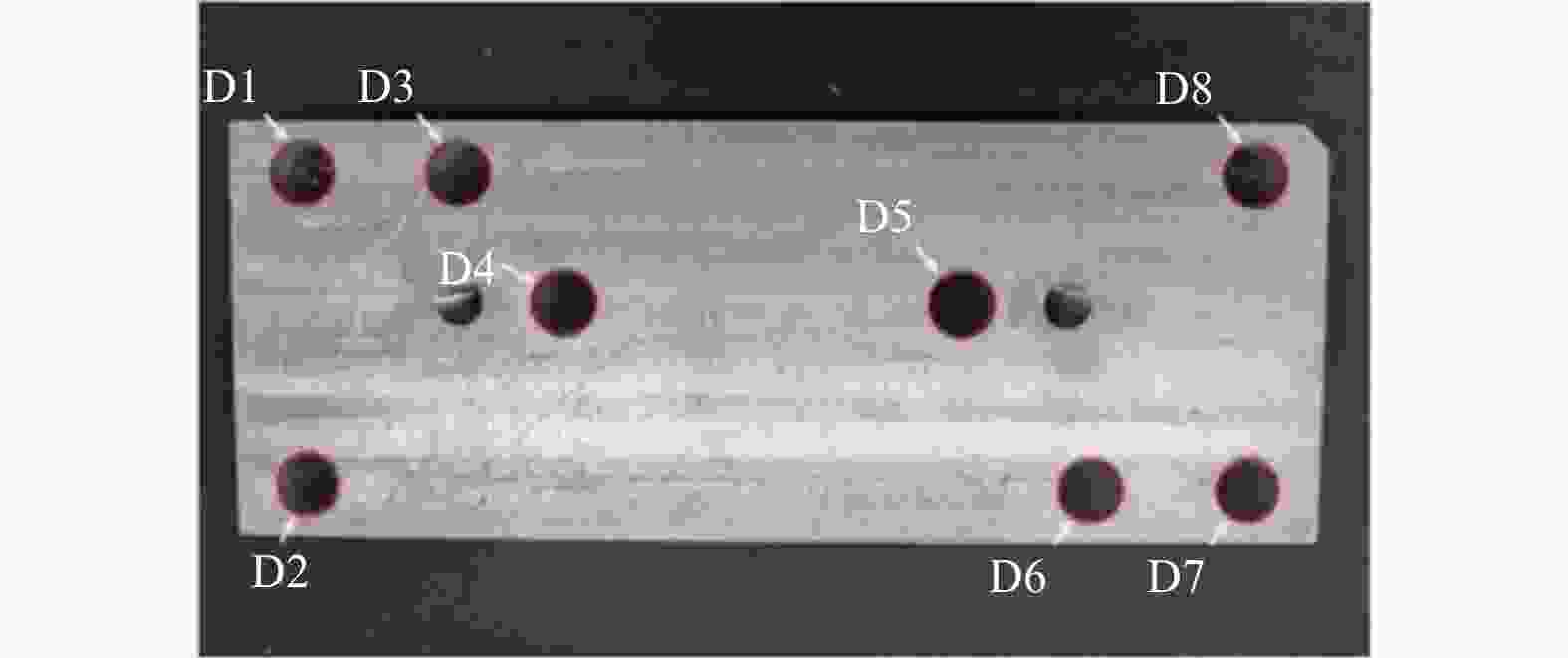

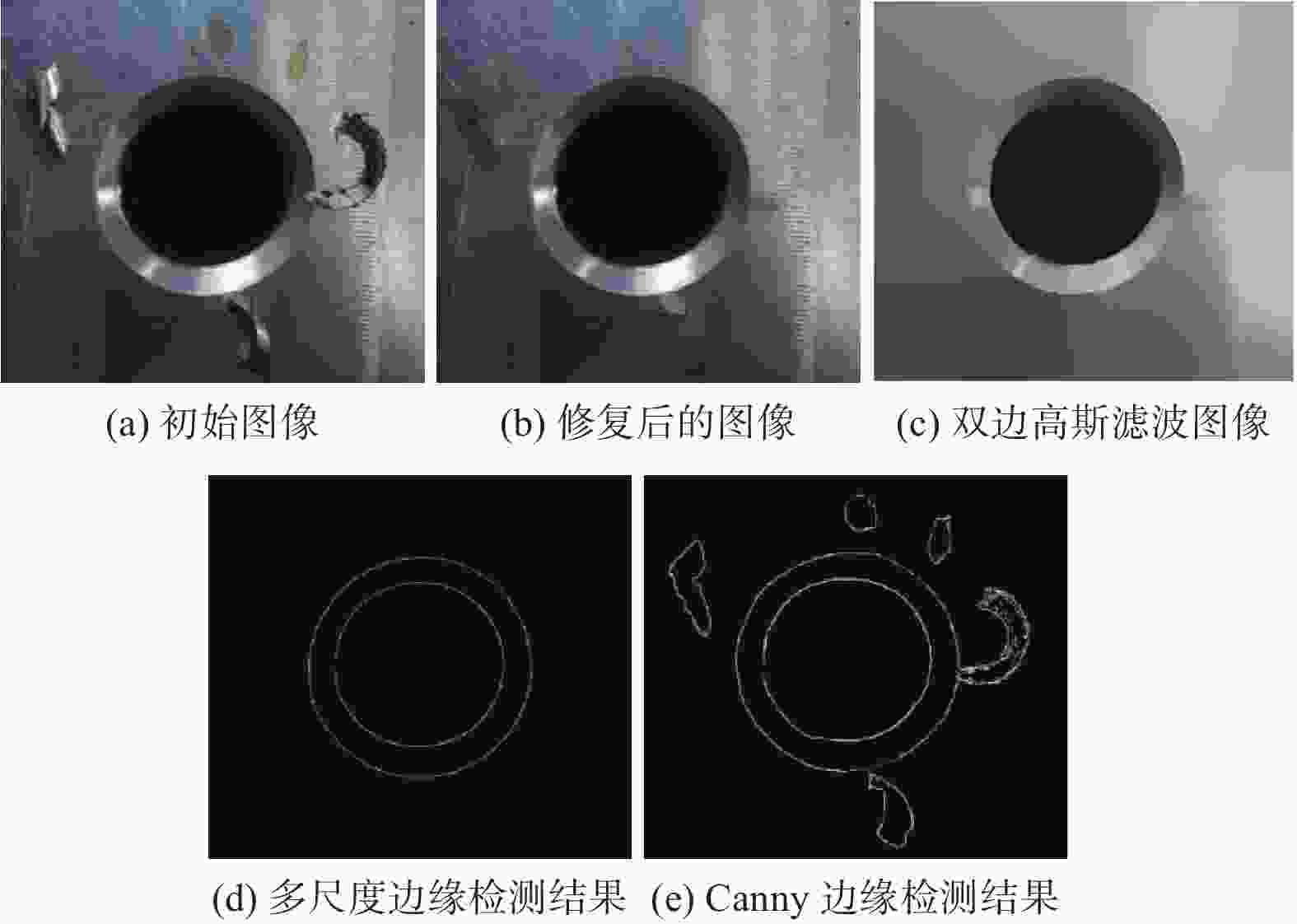

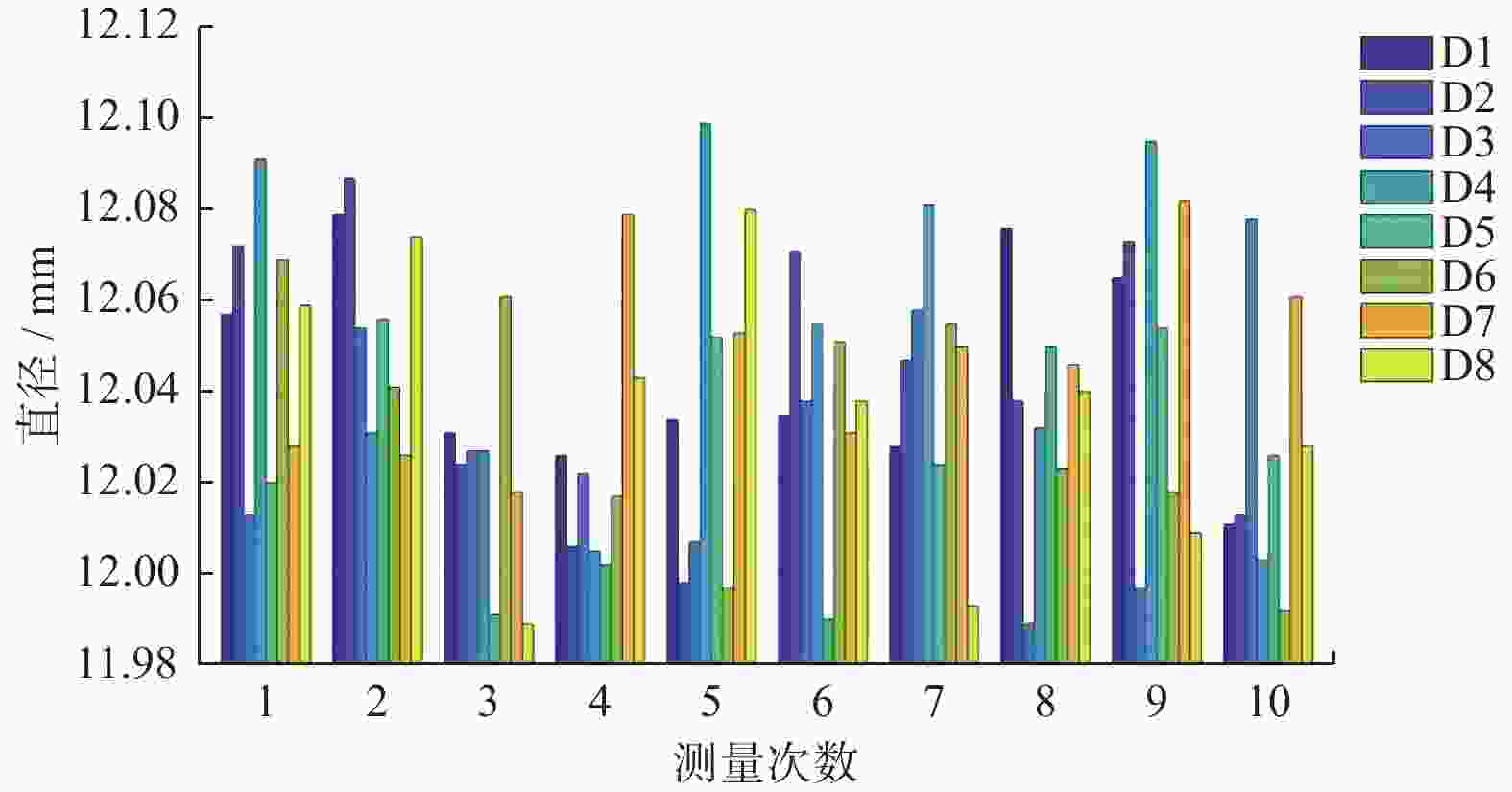

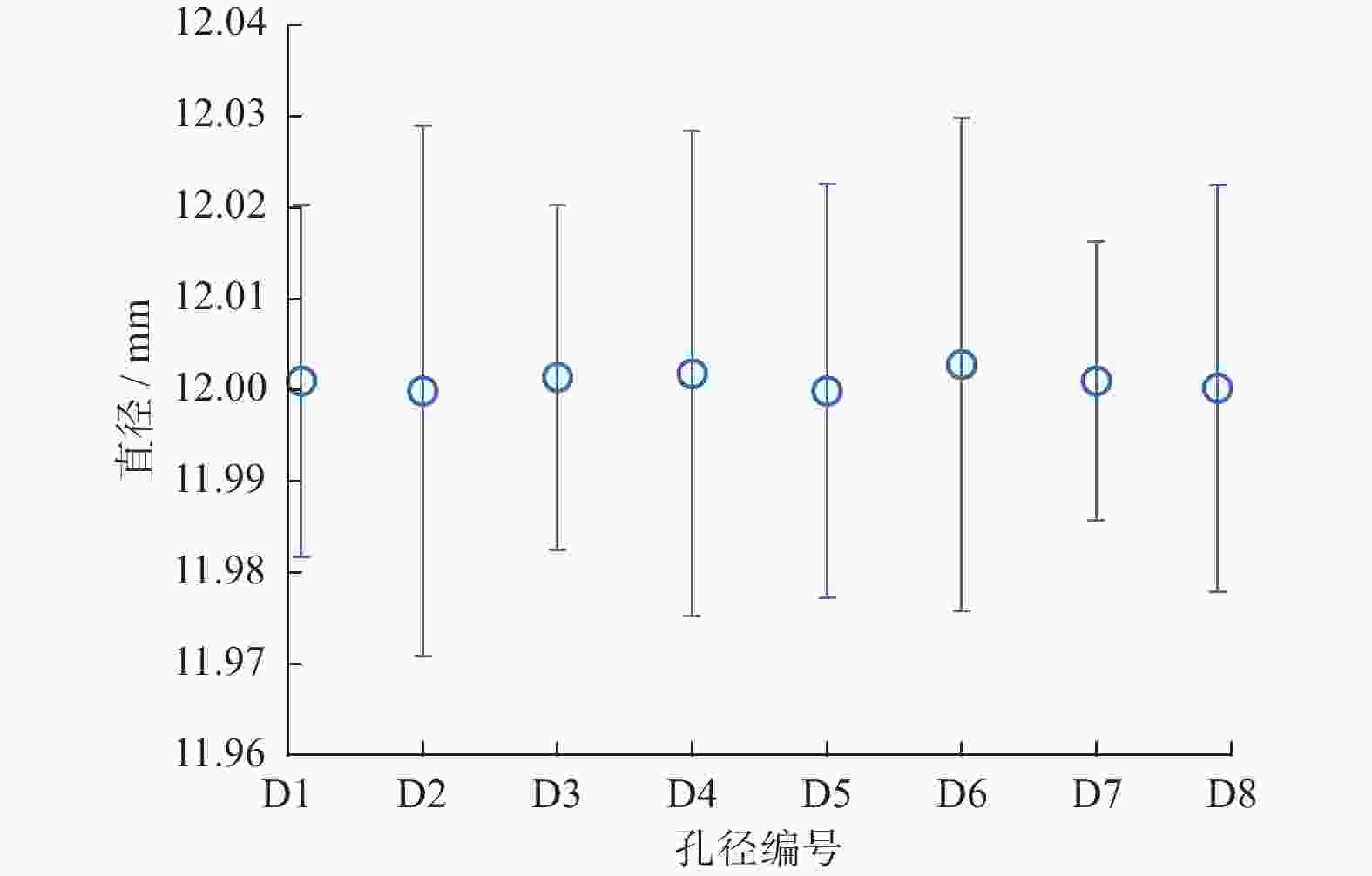

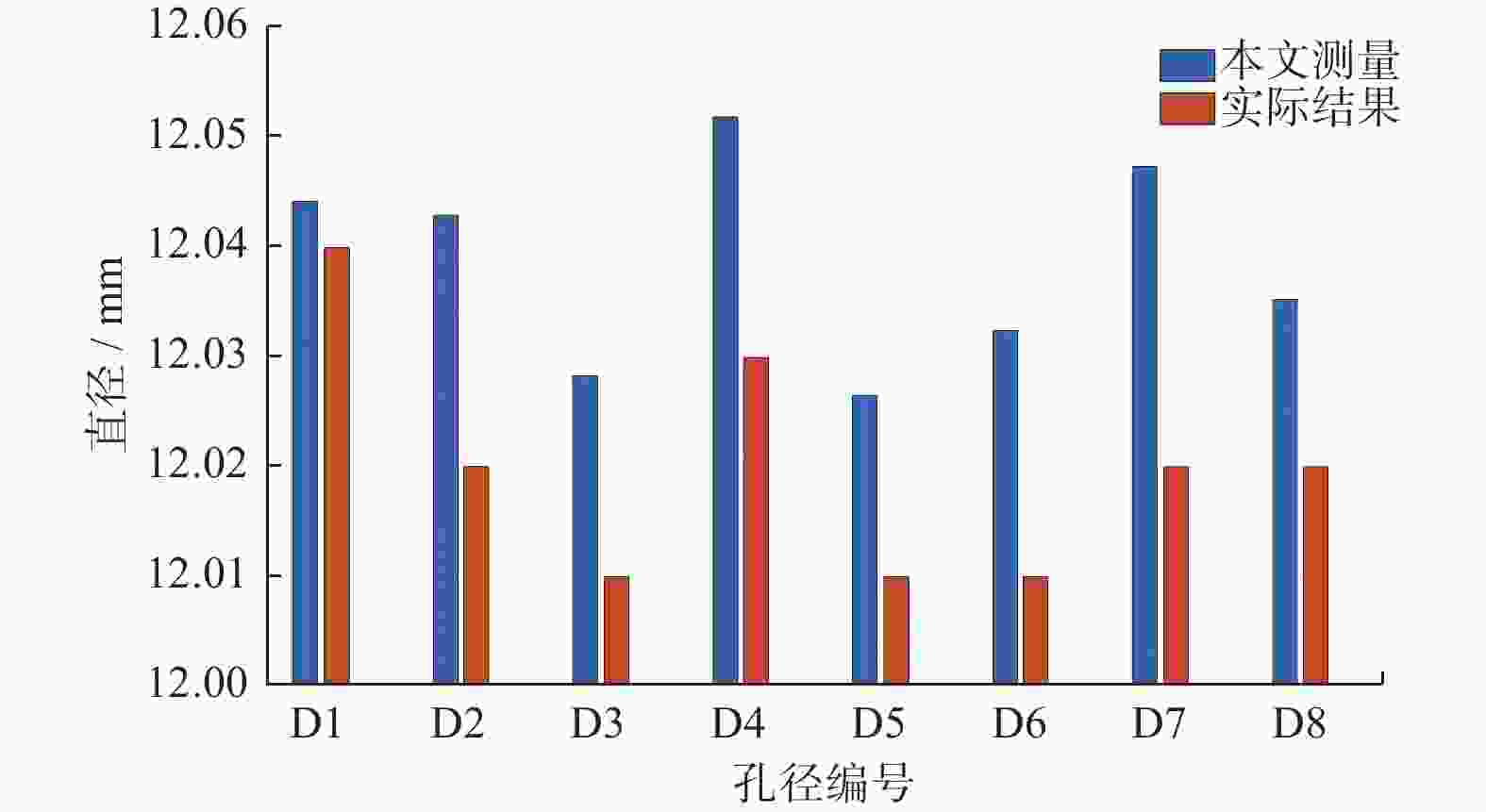

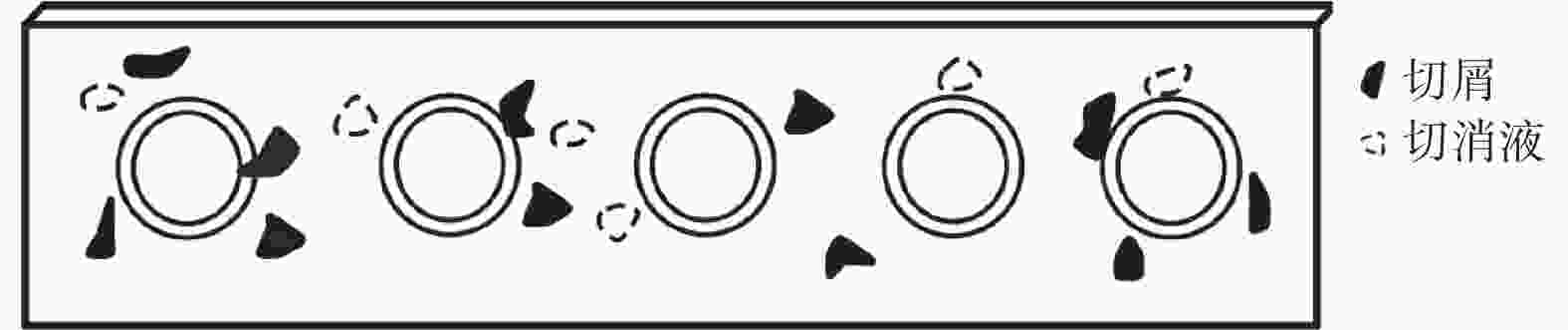

摘要: 在航空铣削零件测量过程中,传统图像处理方法无法有效测量含有切屑和切削液等干扰因素的铣削零件导孔尺寸。针对该问题,提出MPTransUNet模型检测工件图像的干扰区域;采用图像纹理修复方法对检测图像进行修复,并设计了多尺度边缘检测算法提取导孔边缘像素;结合随机抽样一致算法和最小二乘法,对边缘像素点筛选和拟合得到导孔几何尺寸。最后,以航空装夹板件为例验证了该方法的有效性,导孔孔径的测量精度为0.03 mm,可以满足航空铣削零件质检要求。Abstract: In the measurement process of aerospace milling parts, traditional image processing methods cannot effectively measure the size of guide holes in milling parts that contain interference factors such as chips and cutting fluid. To address this issue, a visual measurement method for workpiece aperture based on the TransUNet model was proposed to detect interference regions in the workpiece image, and a mixed pooling module was introduced to improve the model's feature recognition range for chips and cutting fluids. Then, an image direction texture repair method was used to repair the detection image, and the guide hole edge pixels were extracted by improving the edge detection algorithm. Combining the random sampling consensus algorithm and least squares method, the guide hole geometric size was obtained by filtering and fitting the edge pixel points. Finally, the effectiveness of the method was verified by an example of aerospace fixture plate. The measurement accuracy of the guide hole aperture is 0.03 mm, which can meets the requirements of quality inspection for aerospace milling parts.

-

Key words:

- deep learning /

- edge detection /

- image segmentation /

- visual measurement

-

表 1 单因素t检验偏差结果

Table 1. Single sample t-test results of biases

序号 样本量 平均偏差/mm t统计量 P-value 1 10 0.0229 −1.1307 0.2874 2 10 0.0224 −1.1099 0.2958 3 10 0.0274 −1.3618 0.2064 -

[1] 勾江洋. 基于机器视觉的飞机结构件上群排导孔在机检测技术研究[D]. 南京: 南京航空航天大学, 2018. [2] ULLAH U, BHATTI F A, MAUD A R, et al. IoT-enabled computer vision-based parts inspection system for SME 40[J] . Microprocessors and Microsystems,2021,87(10):43 − 54. [3] ZHANG H, LIU J, CHEN S F, et a. Novel roughness measurement for grinding surfaces using simulated data by transfer kernel learning[J] . Applied Soft Computing,2018,73:508 − 519. [4] ZHANG Z Y, WANG X D, ZHAO H T, et al. The machine vision measurement module of the modularized flexible precision assembly station for assembly of micro- and meso-sized parts[J] . Micromachines,2020,11(10):918. [5] BINALI R, KUNTOLU M, PIMENOV D Y, et al. Advance monitoring of hole machining operations via intelligent measurement systems: A critical review and future trends[J]. Measurement, 2022, 201. DOI: 10.1016/j.measurement.2022.111757. [6] 党长营, 贾立功, 曾志强, 等. 基于机器视觉的双金属铸件圆孔测量方法[J] . 制造技术与机床,2021(6):96−99. [7] 陈旭昂, 邓恒, 周建华, 等. 基于机器视觉的钢轨圆孔动态测量方法[J] . 电子测量技术,2022,45(21):111−116. [8] 解则晓, 王晓东, 宫韩磊. 基于双目视觉的薄壁零件圆孔轮廓测量[J] . 中国激光,2019,46(12):171−178. [9] 唐瑞尹, 王荃, 何鸿鲲, 等. 基于小波变换和数学形态学的孔径测量研究[J] . 应用光学,2017,38(4):622−626. [10] 张雪峰, 闫慧. 基于中值滤波和分数阶滤波的图像去噪与增强算法[J] . 东北大学学报(自然科学版),2020,41(4):482 − 487. [11] 邓斌攸, 池志强, 潘云峰, 等. 家具板件圆形孔位的机器视觉在线检测算法[J] . 木材科学与技术,2022,36(2):60 − 64. [12] LI X, YANG Y, YE Y, et al. An online visual measurement method for workpiece dimension based on deep learning[J]. Measurement, 2021, 185. DOI: 10.1016/j.measurement.2021.110032. [13] YI H A, LIU J, AO P, et al. Visual method for measuring the roughness of a grinding piece based on color indices[J] . Optics Express,2016,24(15):17215 − 17233. [14] RIFAI A P, AOYAMA H, THO N H, et al. Evaluation of turned and milled surfaces roughness using convolutional neural network[J] . Measurement,2020,161:107860. doi: 10.1016/j.measurement.2020.107860 [15] RAVIMAL D, KIM H, KOH D, et al. Image-based inspection technique of a machined metal surface for an unmanned lapping process[J] . International Journal of Precision Engineering and Manufacturing-Green Technology,2020,7(3):547 − 557. doi: 10.1007/s40684-019-00181-7 [16] 丁莉, 苏倩. 基于纹理的图像修复的技术的研究[J] . 自动化与仪器仪表,2016(7):150 − 151. [17] OTSU N. A threshold selection method from gray-level histograms[J] . IEEE Transactions on Systems Man & Cybernetics,2007,9(1):62 − 66. [18] CHEN C S, HUNG Y P, CHENG J B. RANSAC-based DARCES: A new approach to fast automatic registration of partially overlapping range images[J] . IEEE Transactions on Pattern Analysis & Machine Intelligence,2002,21(11):1229 − 1234. [19] ZHANG Z Y. Flexible camera calibration by viewing a plane from unknown orientations[C]// Proceedings of the Seventh IEEE International Conference on Computer Vision. Redmond: IEEE, 1999. -

下载:

下载: