Research progress in additively manufactured of selective laser melting 316 stainless steel

-

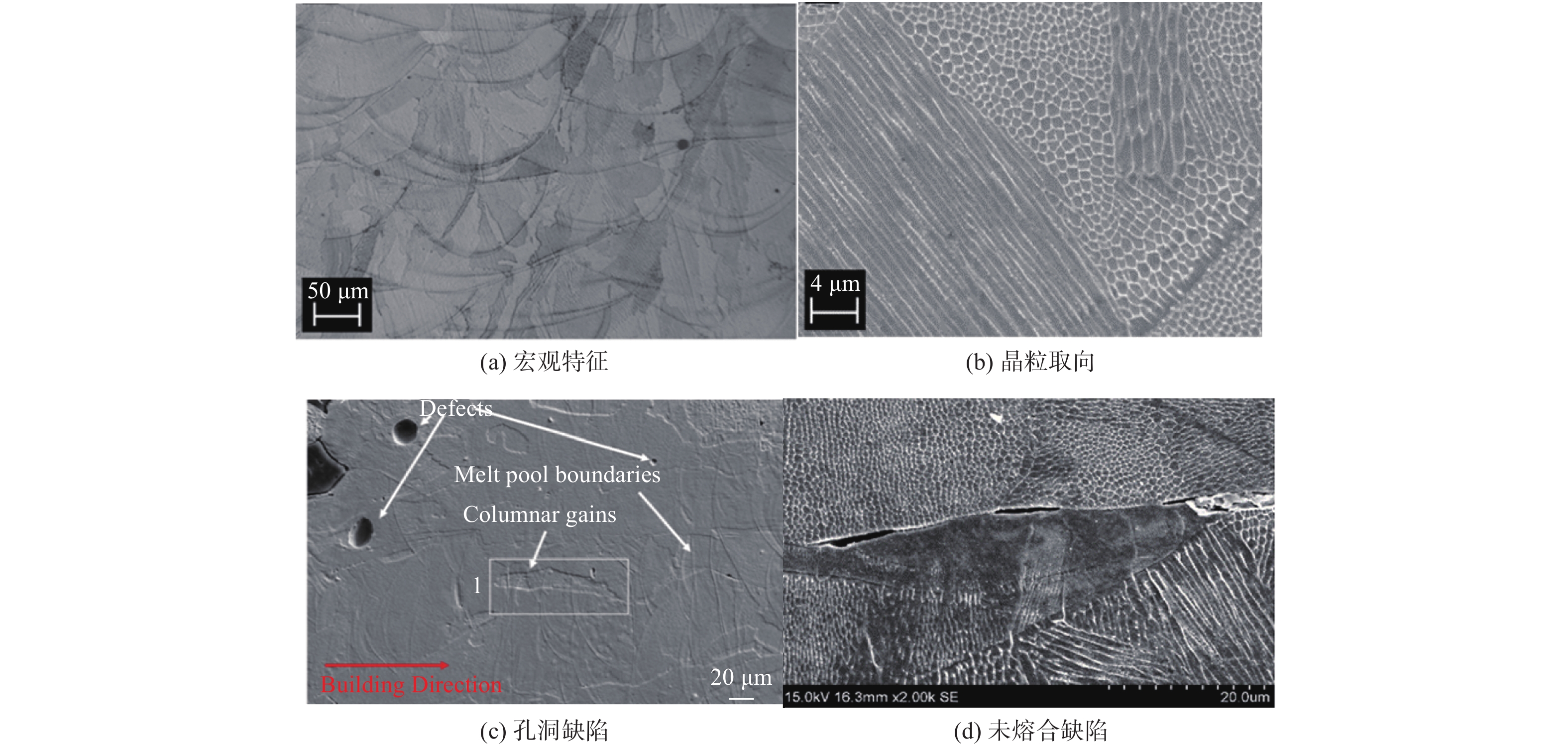

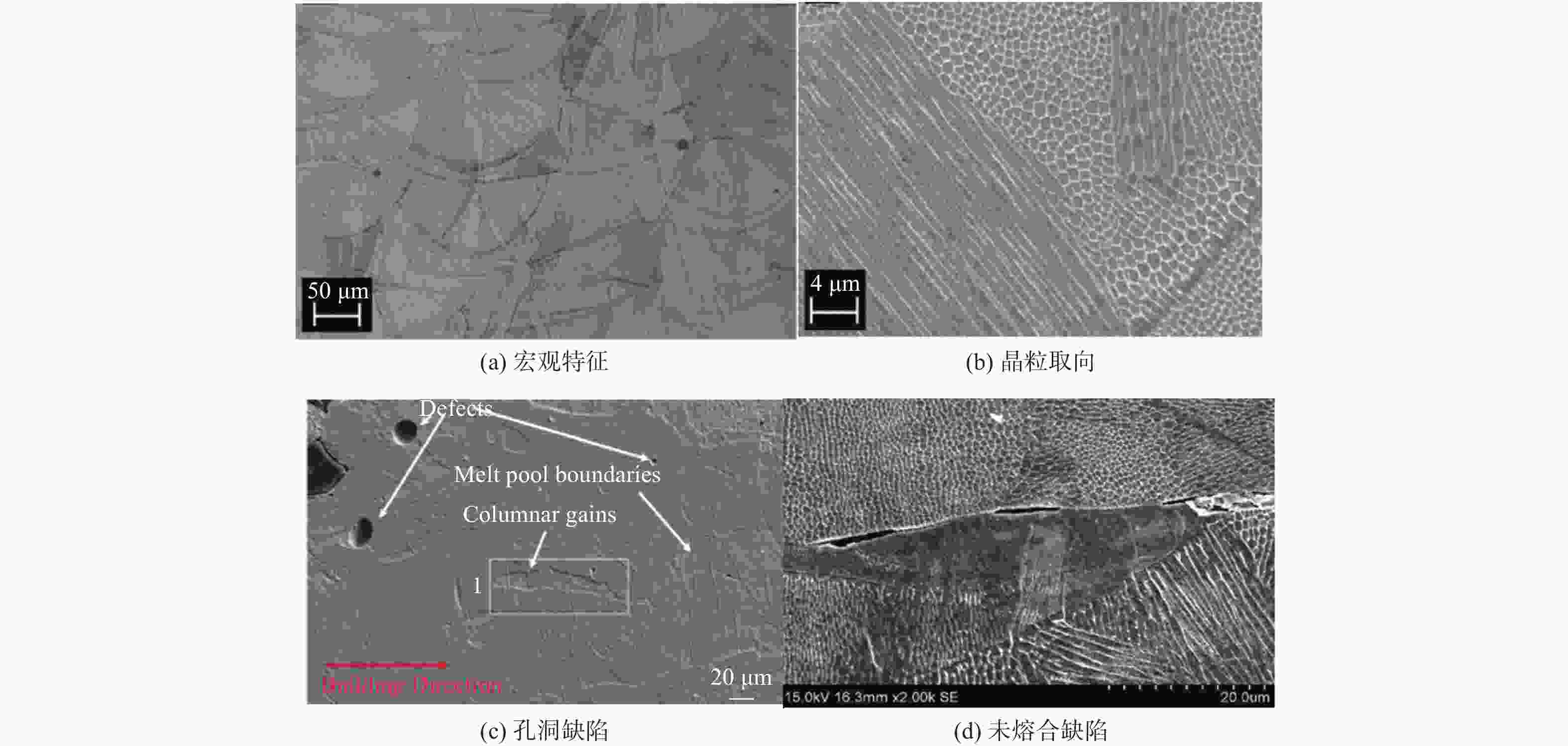

摘要: 激光选区熔化(selective laser melting, SLM)技术在航天汽车等金属增材制造领域具有广阔的应用前景。总结SLM316不锈钢材料在工艺、组织、性能和应用等方面的研究进展,分析探讨存在的问题与解决方法。分析SLM生产加工过程中生产工艺、产品质量和性能稳定性及后处理工艺等流程中存在的问题,进一步研究316不锈钢增材显微组织和力学特性,分析工艺过程对组织和性能的影响,合理控制激光增材制造成形过程,为技术在产业应用提供支撑。Abstract: Selective laser melting (SLM) technology has broad application prospects in the fields of metal additive manufacturing, aerospace vehicles, etc. The research progress of SLM316 stainless steel materials in terms of process, structure, properties, and applications were summarized, and the existing problems and solutions were analyzed and explored. The problems in the production process, product quality, performance stability, and post-treatment process of SLM were analyzed. The microstructure and mechanical properties of 316 stainless steel additive were further studied. influences of the process on the microstructure and properties were analyzed. By reasonably controlling the laser additive manufacturing process, it can provide support for the application of the technology in the industry.

-

Key words:

- vehicle engineering /

- laser melting /

- welding procedure /

- research review

-

表 1 4种不同工艺参数下拉伸性能指标

Table 1. Tensile performance indicators under four different process parameters

工艺参数 性能指标 激光功率/W 扫描速度/(mm·s-1) 层厚度/mm 弹性模量/MPa 屈服强度/MPa 抗拉轻度/MPa 伸长率/% 320 650 0.05 103 ± 3 — 596 ± 10 28.1 ± 2 220 960 0.04 — — 684.7 ± 4.7 27.25 ± 3.35 200 — — — 554 ± 4.6 — 36.3 ± 2.1 230 800 30 — — 720.3 — 表 2 不同扫描策略下316不锈钢的拉伸性能结果

Table 2. Tensile performance results of 316 stainless steel under different scanning strategies

样品 屈服强度/MPa 抗拉强度/MPa 伸长率/% 面积减少/% 偏差范围/% 漫步式 555 684 50.7 70.5 5 ± 0.3 561 688 50.9 72.8 5 ± 0.3 棋盘式5 × 5 mm 546 684 49.5 72.3 5 ± 0.3 535 677 52.7 70.0 5 ± 0.3 棋盘式1 × 1 mm 519 664 45.3 55.4 5 ± 0.3 518 662 48.1 63.1 5 ± 0.3 文献[9]实验 554 685 36.0 5 ± 0.3 文献[19]实验 487 594 49.0 58.0 5 ± 0.3 文献[13]实验 590 700 36.0 5 ± 0.3 文献[15]实验 450 640 59.0 5 ± 0.3 热加工 + 退火 170 480 40.0 50.0 5 ± 0.3 冷加工 + 退火 170 480 30.0 40.0 5 ± 0.3 冷加工 310 620 30.0 40.0 5 ± 0.3 表 3 SLM和热处理样品的屈服强度和极限抗拉强度的平均值

Table 3. Average values of yield strength and ultimate tensile strength of SLM and heat treated samples

测试样品 屈服强度/MPa 抗拉强度/MPa SLM 550 ± 10 1016 ± 8 573 K 459 ± 3 969 ± 5 873 K 440 ± 3 941 ± 4 1273 K 347 ± 8 836 ± 7 1373 K 243 ± 5 814 ± 7 1673 K 174 ± 7 712 ± 4 -

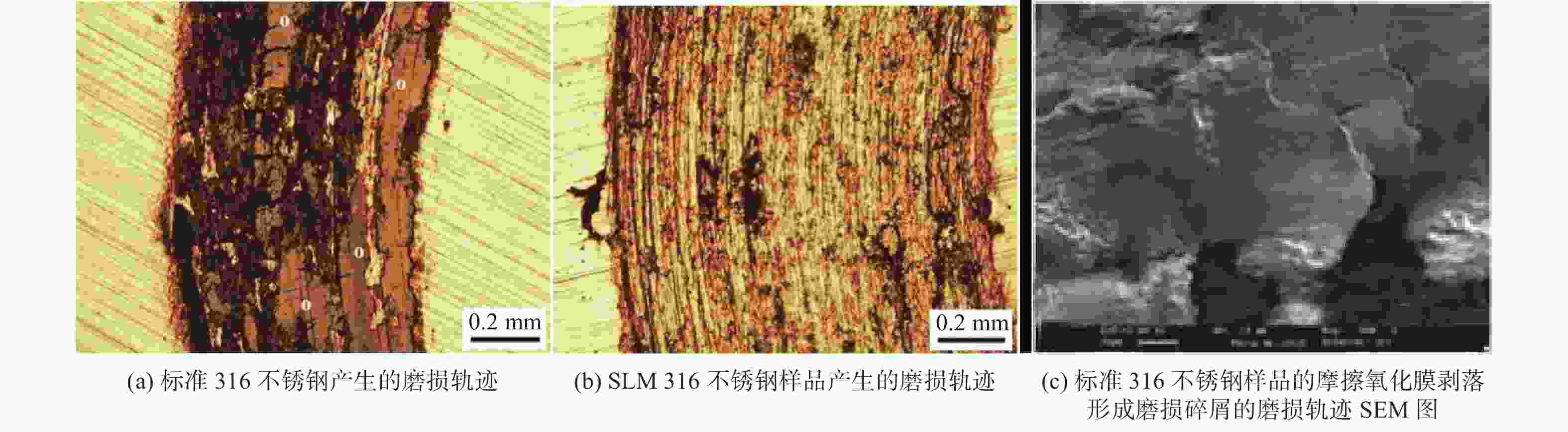

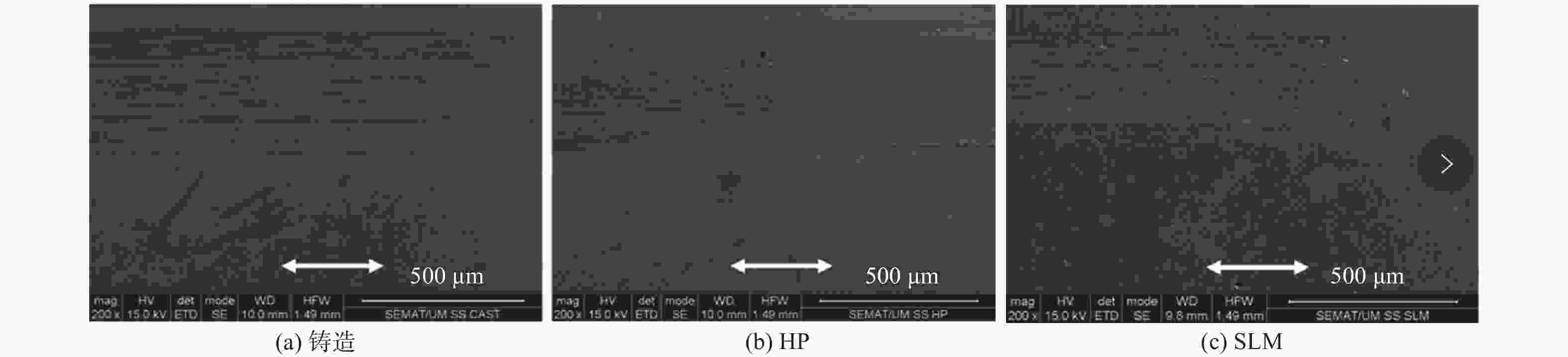

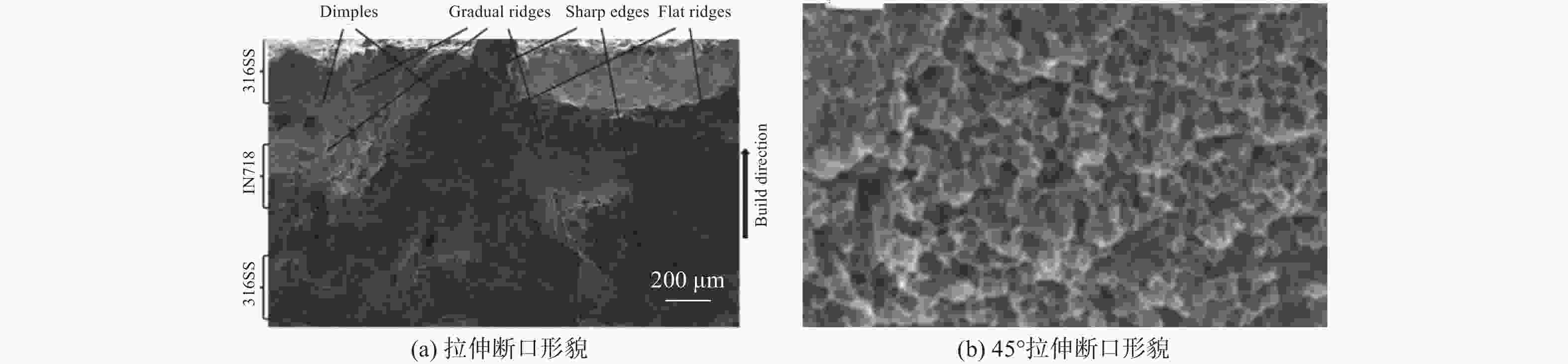

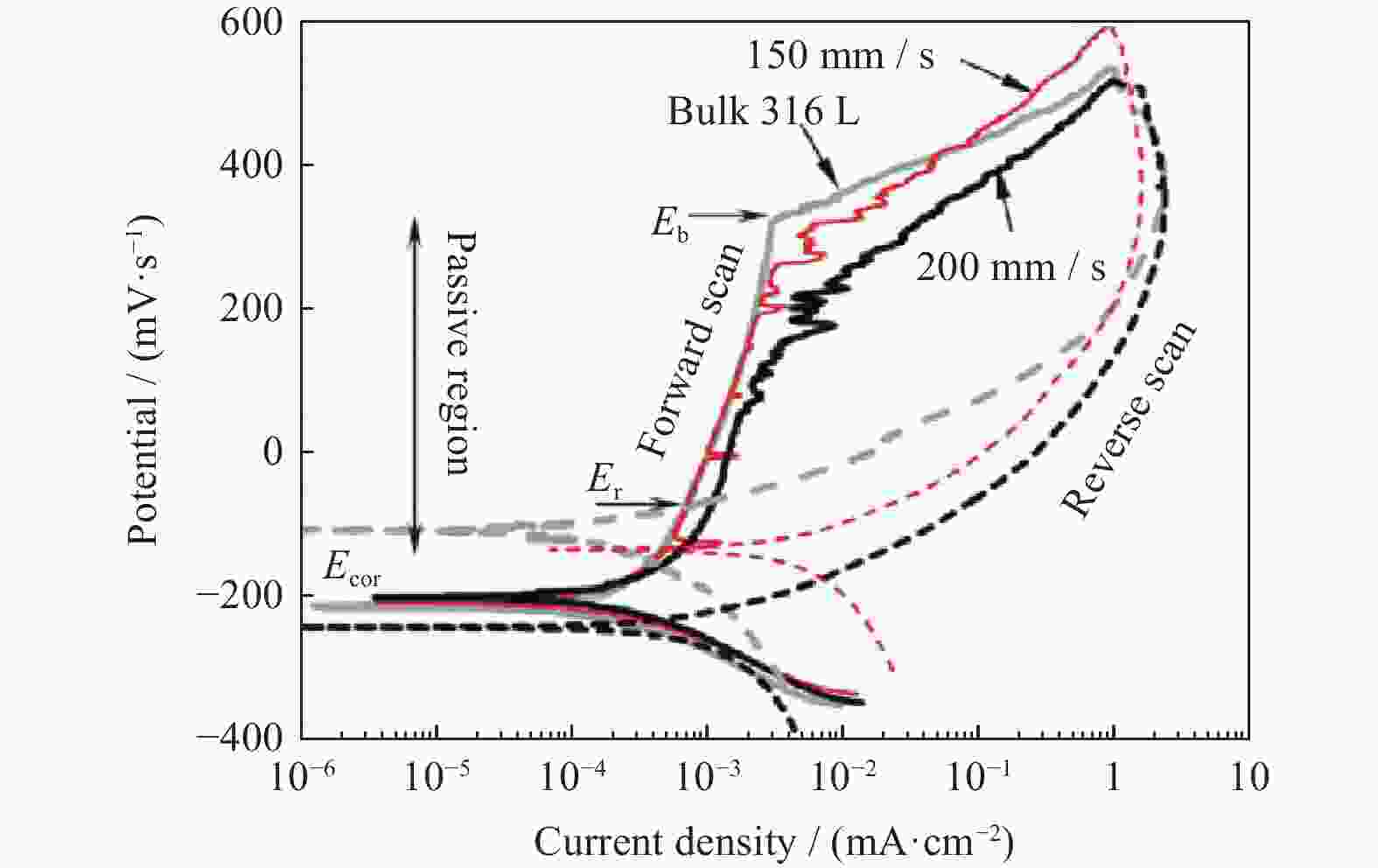

[1] RIEMER A, LEUDER S, THONE M, et al. On the fatigue crack growth behavior in 316L stainless steel manufactured by selective laser melting[J] . Engineering Fracture Mechanics, 2014, 120: 15 − 25. [2] CARROLL B E, PALMER T A, BEESE A M. Anisotropic tensile behavior of Ti-6Al-4V components fabricated with directed energy deposition additive manufacturing[J] . Acta Materialia, 2015, 87: 309 − 320. [3] THIJS L, VERHAEGHE F, CRAEGHS T, et al. A study of the microstructural evolution during selective laser melting of Ti–6Al–4V[J] . Acta Materialia,2010,58(9):3303 − 3312. doi: 10.1016/j.actamat.2010.02.004 [4] ZAEH M F, BRANNER G. Investigations on residual stresses and deformations in selective laser melting[J] . Production Engineering,2010,4(1):35 − 45. doi: 10.1007/s11740-009-0192-y [5] YUSUF S M, CHEN Y F, BOARDMAN R, et al. Investigation on porosity and microhardness of 316L stainless steel fabricated by selective laser melting[J] . Metals,2023,39(7):64 − 72. [6] 丁利, 李怀学, 王玉岱, 等. 热处理对激光选区熔化成形 316不锈钢组织与拉伸性能的影响[J] . 中国激光,2015(4):179 − 185. [7] SUN Z J, TAN X P, TOR S B, et al. Selective laser melting of stainless steel 316L with low porosity and high build rates[J] . Materials & Design, 2016, 104: 359−359 − 3359 − 369. [8] LIVERANI E, TOSCHI S, CESCHINI L, et al. Effect of selective laser melting (SLM) process parameters on microstructure and mechanical properties of 316L austenitic stainless steel[J] . Journal of Materials Processing Technology,2017,249:255 − 263. [9] CASATI R, LEMKE J, VEDANI M. Microstructure and fracture behavior of 316L austenitic stainless steel produced by selective laser melting[J] . Journal of Materials Science & Technology, 2016, 49(15): 739 − 740. [10] ZHENG Z, WANG L, YAN B. Effects of laser power on the microstructure and mechanical properties of 316L stainless steel prepared by selective laser melting[J] . International Journal of Modern Physics B,2017,31(16/19):174 − 186. [11] LODHIA M J K, DEENB K M, GREENLEE M C, et al. Additiely manufactured 316L stainless steel with improved corrosion resistance and biological response for biomedical applications[J] . Additive Manufacturing, 2019, 27: 8−8 − 19. [12] SAEIDI K, GAO X, ZHANG Y, et al. Hardened austenite steel with columnar sub-grain structures formed by laser melting[J] . Materials Science and Engineering: A, 2015, 625: 221 − 229. [13] WANG Z, GAO D. Friction and wear properties of stainless steel sliding against polyetheretherketone and carbon-fiber-reinforced polyether ether ketone under natural seawater lubrication[J] . Materials & design,2014,53(1):881 − 887. [14] BARTOLOMEUA F, BUCIUMEANU M, PINTO E, et al. 316L stainless steel mechanical and tribological behavior: A comparison between selective laser melting, hot pressing and conventional casting[J] . Additive Manufacturing,2017,25(12):81 − 89. [15] WANG P F, HAN Z. Friction and wear behaviors of a gradient nano-grained AISI 316L stainless steel under dry and oil-lubricated conditions[J] . Journal of Materials Science & Technology,2018,34(10):125 − 132. [16] ZHANG Z, CHU B, WANG L, et al. Comprehensive effects of placement orientation and scanning angle on mechanical properties and behavior of 316L stainless steel based on the selective laser melting process[J] . Journal of Alloys and Compounds, 2019, 791: 166 − 175. [17] SUN Y, MOROZ A, ALRBAEY K. Sliding wear characteristics and corrosion behaviour of selective laser melted 316L stainless steel[J] . Journal of Materials Engineering and Performance,2014,23(2):215 − 223. [18] CASATI R, LEMKE J, VEDANI M. Microstructure and fracture behavior of 316L austenitic stainless steel produced by selective laser melting[J] . Journal of Materials Science & Technology, 2016, 32(8): 738−738 − 7738 − 744. [19] ZHONG Y, LIU LF, WIKMAN S, et al. Intragranular cellular segregation network structure strengthening 316L stainless steel prepared by selective laser melting[J] . Journal of Nuclear Materials, 2016, 470: 170 − 178. [20] ZHAO H, HUMBEECK JV, SOHIER J, et al. Electrochemical polishing of 316L stainless steel slotted tube coronary stents[J] . Journal of Materials Science. Materials in Medicine, 2002, 13(10): 911 − 916. [21] EHSANI A, MAHJANI MG, MOSHREFI R, et al. Electrochemical and DFT study on the inhibition of 361L stainless steel corrosion in acidic medium by 1-(4-nitrophenyl)-5-amino-1H- tetrazole[J] . RSC Advances,2014,4(38):2003 − 2010. [22] LUO J P, JIA X, GU R N, et al. 316L stainless steel manufactured by selective laser melting and its biocompatibility with or without hydroxyapatite coating[J] . Metals, 2018, 8(7): 548 − 555. doi: 10.3390/met8070548 [23] MEI X , WANG X , PENG Y, et al. Interfacial characterization and mechanical properties of 316L stainless steel/inconel 718 manufactured by selective laser melting[J] . Materials Science and Engineering,2019(758):185 − 191. [24] QIU C, KINDI M A , ALADAWI A S, et al. A comprehensive study on microstructure and tensile behaviour of a selectively laser melted stainless steel[J] . Scientific Reports, 2018, 8(1): 7785. [25] SALMANA O O, GAMMER C, CHAUBEY A K, et al. Effect of heat treatment on microstructure and mechanical properties of 316L steel synthesized by selective laser melting[J] . Materials Science & Engineering, 2019, 748: 205 − 212. [26] Prashanth K G, Eckert J. Formation of metastable cellular microstructures in selective laser melted alloys[J] . Journal of Alloys and Compounds, 2017, 707: 27 − 34. [27] KARGAR B S, MOAYED M H, BABAKHANI A, et al. Improving the corrosion behaviour of powder metallurgical 316L alloy by prepassivation in 20% nitric acid[J] . Corrosion Science, 2011, 53(1): 135 − 146. doi: 10.1016/j.corsci.2010.09.004 -

下载:

下载: